- 吳德峰 教授

- 揚(yáng)州大學(xué)化學(xué)化工學(xué)院

- 網(wǎng)址: wudefeng.polymer.cn 訪問(wèn)量:1184631

- BRGers-主頁(yè)

- Researcher ID

- 化學(xué)化工學(xué)院

- 中國(guó)聚合物網(wǎng)

- 中國(guó)流變網(wǎng)

- 中國(guó)化學(xué)儀器網(wǎng)

- 化學(xué)化工論壇

- 通信地址:揚(yáng)州大學(xué)化學(xué)化工學(xué)院810信箱

- 郵編:225002

- 電話:0514-87975230

- 傳真:0514-87975244

- Email:dfwu@yzu.edu.cn

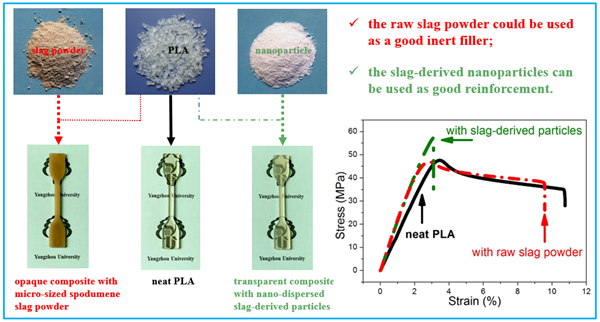

關(guān)鍵字:spodumene slag; silica; polylactide; green composites; reinforcements.

論文來(lái)源:期刊

具體來(lái)源:RSC Advances

發(fā)表時(shí)間:2016年

RSC Advances, 2016, 6, 36942-36953.

ABSTRACT:

Nowadays spodumene ores become an important lithium resource. The generated slag, as the new member of slag family, would make the environmental burden mount up. Therefore, recycling of spodumene slag was studied in this work, with the objective of exploring the possibility of spodumene slag to be used as a common polymer filler. The microsized slag powder was firstly incorporated with polylactide (PLA) through solution mixing, followed by the injection molding, and the obtained composites were then studied in terms of morphology, rheological and mechanical properties, as well as creep and degradation behavior. The results reveal that the presence of slag powder enhances the system modulus evidently, while maintains normal strength level of PLA. Therefore, the slag powder can be used as a good inert filler in the polymeric material industry, with desirable reduction of cost. Then, the slag powder was further refined into nanoparticles, and again mixed with PLA. The results show that the presence of those nanoparticles increases both the modulus and strength remarkably because of their good dispersion and distribution in PLA matrix. As a result, those spodumene slag-derived nanoparticles can be used as a good reinforcement or as the active filler in the polymer additive industry. Both the slag powder and slag-derived nanoparticles highly restrain creep of PLA chain, while promote degradation of PLA remarkably. Therefore, those particles can be well used to tailor the final properties of PLA. In addition, a modified model was developed successfully to predict mechanical strength of as-obtained green composites. This work provides a new way to fabricate a novel green polymer composite with controllable performance by recycling of spodumene slag.

PDF DOWNLOAD:

http://pubs.rsc.org/en/content/articlepdf/2014/RA/C6RA03119F?page=search